- Home Page

- Company Profile

-

Our Products

- Level Switches

- Conductivity Level Switch

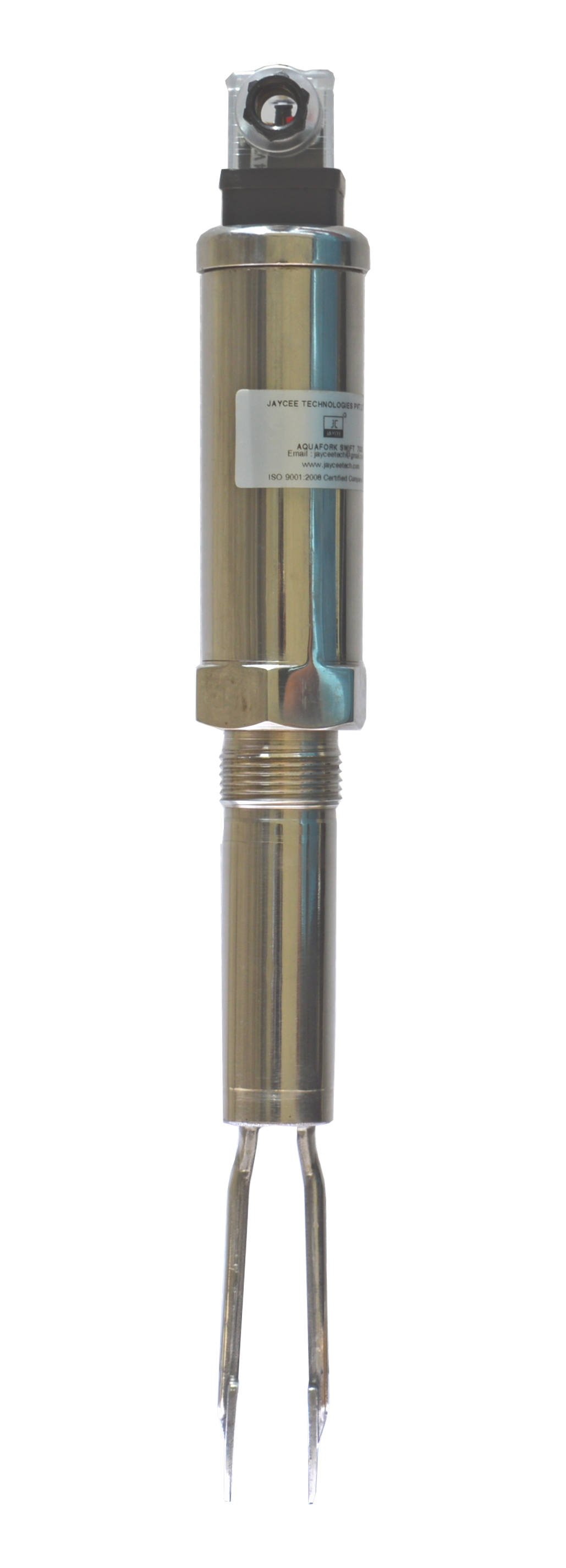

- Vibrating Fork Level Switch for Solid Application

- Admittance Point Level Switches

- RF Level Switches for ESP Hopper

- Rotating Paddle Point Level Switches

- Boot Level Switches

- 002 RF Level Switch

- Float Level Switch

- Honeybee Level

- Liquid Tuning Fork Point Level Switch

- Vibrating Rod Point Level Switches

- 006 vibrating fork Harp

- 005 Conducttivity Level Switch

- 003 Roating Paddle level switch

- Vibrating Fork Level Switch

- Flow Meters

- Level Transmitters

- Moisture Sensors

- Radar Level Transmitter

- Ultrasonic Level Transmitter

- Level Switches

- Contact Us

Vibrating Fork Level Switch for Solid Application

MOQ : 1 Piece

Vibrating Fork Level Switch for Solid Application Specification

- Finish Type

- Electro-polished

- Mechanical Life

- Over 10 million operations

- Automation Grade

- Automatic

- Circuit Type

- SPDT relay output

- Max. Current

- 10A

- Rated Voltage

- 220-250V AC

- Response Time

- <1 second

- Protection Level

- IP66/IP67

- Number of Module

- Single

- Temperature Range

- -20C to +80C

- Product Type

- Fork Level Switch

- Material

- Stainless Steel

- Insulation Resistance

- 100 M at 500V DC

- Contact Resistance

- 100 m

- Max. Voltage

- 250 V AC

- Operating Temperature

- -20C to +80C

- Size

- Customizable, Standard 250mm (other lengths on request)

- Color

- Silver

- Weight

- Approx. 1.8 kg

- Mounting Type

- Threaded or Flanged

- Current Rating

- 5-10A

- No Of Poles

- Single Pole

- Process Connection

- 1-1/2" BSP/NPT thread or Flange

- Explosion Proof

- Optional, on request

- Ambient Temperature

- -40°C to +70°C

- Fail Safe Mode

- Selectable (High/Low level fail safe)

- Output Signal

- Relay (SPDT), max 250V AC 5A

- Power Supply

- 18~253V AC/DC, 50/60Hz

- Cable Entry

- M20 x 1.5

- Vibration Amplitude

- Approx. 1 mm

- Fork Frequency

- Approx. 350 Hz

- Housing Material

- Aluminum Alloy

- Application

- Level detection for granular and powdered solids

- Working Pressure

- Max 10 bar

Vibrating Fork Level Switch for Solid Application Trade Information

- Minimum Order Quantity

- 1 Piece

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Vibrating Fork Level Switch for Solid Application

Theelectronically Stimulated Fork Vibrates At Its Mechanicallyresonance Frequency Of About 400 Hz When The Fork Is Free Of Theservice Material. The Resonance Is Caused By The Piezoelectriccrystals. One Of The Piezo Crystals Produces A Small Voltage Which Istransmitted To The Switching Amplifier. If The Fork Is Covered By Thebulk Material, A Damping Effect Is Produced And The Piezo Crystaldoes Not Produce The Voltage And The Amplifier Will Switch And Acorresponding Signal Output Is Actuated. The Vibration Of The Forkhas Self-Cleaning Properties.

The light Deposit On The Container Wall Does Not Affect The Operation Ofthe Aqua fork

Applications:

Mostliquids With Max 10000 Mm2/S Viscosity. Corressive, Thick, Turbulent,Flowing Liguids.

Powdersand Light Granules With Min. Density 0.05 Kg/Dm3

Robust Detection for Bulk Solid Applications

This vibrating fork level switch excels at detecting levels of granular and powdered materials in silos, hoppers, and process bins. Engineered to work under high pressure and varied temperature ranges, it delivers continuous, accurate monitoring, ensuring operational safety and efficiency in bulk material handling industries.

Flexible Installation and Operation

With customizable probe lengths, multiple mounting options (threaded or flanged), and universal power compatibility, this device is versatile enough for new installations or retrofits. The selectable fail-safe mode and rapid response time (<1 second) guarantee reliable performance tailored to process requirements.

FAQs of Vibrating Fork Level Switch for Solid Application:

Q: How does the vibrating fork level switch detect solid material levels?

A: It utilizes rapid vibration at approximately 350 Hz; when solids contact the fork, vibration is dampened, triggering the relay output (SPDT). This ensures accurate level detection for both granular and powdered materials.Q: What installation options are available for this level switch?

A: The device supports both threaded (1-1/2" BSP/NPT) and flanged process connections, with standard probe lengths of 250mm and customizable sizes available on request. It mounts easily into silos, hoppers, or bins.Q: When should I use the fail-safe mode, and how do I select it?

A: Fail-safe mode safeguards against malfunction by switching the relay on high or low-level detection failure. Selection can be made during device setup, tailoring response to either overfill or empty conditions as per process needs.Q: Where is the vibrating fork level switch commonly used?

A: Its robust design makes it suitable for bulk solids storage and handling in food, cement, chemical, and pharmaceutical industries, especially where safe and reliable level monitoring is critical.Q: What benefits does the vibration amplitude and rapid response provide?

A: The approx. 1 mm vibration amplitude and response time of under one second result in highly sensitive detection and minimal lag, supporting uninterrupted and safe operation within demanding environments.Q: What is the maximum process pressure and operating temperature range supported?

A: This switch operates effectively up to 10 bar pressure and within a temperature range of -20C to +80C, allowing for deployment in challenging industrial zones.Q: Is explosion-proof certification available for hazardous environments?

A: Yes, explosion-proof versions can be provided on request to ensure safe operation in potentially explosive atmospheres. Consult the supplier for details regarding compliant models.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Level Switches Category

Vibrating Rod Point Level Switches

Price 6400-20000 INR

Minimum Order Quantity : 150 Units

Material : Stainless Steel

Product Type : Vibrating Rod Point Level Switches

Color : Silver Blue

Finish Type : Polished

Boot Level Switches

Price 6400-20000 INR

Minimum Order Quantity : 150 Units

Material : High Impact Polypropylene

Product Type : Level Switches

Color : Grey

Finish Type : Textured

Vibrating Fork Level Switch

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Product Type : Vibrating Level Switch

Color : Silver

Finish Type : Polished Stainless Steel

003 Roating Paddle level switch

Price 7000.0 INR

Minimum Order Quantity : 1

Material : MS

Product Type : Roating Paddle

Color : Blue

Finish Type : Smooth

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free